Quality

Quality control in luggage production

Fusheng Luggage Manufacturing is committed to ensuring that every luggage we produced meets the highest industry standards through a series quality control process.

In-house Testing Lab for Luggage Quality

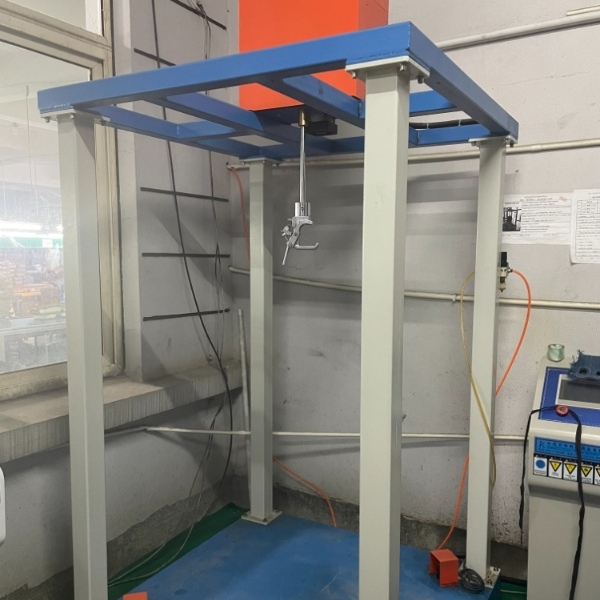

Our factory’s own testing lab is equipped with wheel durability test machine, trolley handle test machine, tumble test machine and drop test machine. These testing machines ensure the suitcase we produced meet the highest standards of durability, reliability and practicality. We also have a professional team who strictly monitor and analyze data of testing result. Through these integrated tests, we can promptly identify and resolve potential quality issues, thereby continuously enhancing the quality and customer satisfaction of our products.